Comprehensive Corrosion Monitoring

MarineLinx is a modular, cloud-based corrosion monitoring system.

-

The Problem

Vessel corrosion problems are typically identified after significant damage has occurred, with the diagnosis often complex and misunderstood.

-

The Solution

MarineLinx is an advanced corrosion monitoring system that offers real-time fault detection.

Designed to be modular and expandable, MarineLinx monitors critical corrosion risks on all types of vessels, such as stray current, insulation failure, shore power influences, cathodic protection deficiencies, earthing faults and environmental impacts.

-

The Result

Preventative action empowers vessel operators to make informed decisions ensuring safety, efficiency and reduction of expensive repairs.

Traditionally stray current monitoring has been reserved for very high-end builds, are custom built solutions, and are very rarely actively monitored.

Our technical experience surveying boats for corrosion issues over the last 15 years has provided an exceptional infield understanding and technical expertise that has been translated into the information supplied by MarineLinx.

MarineLinx is designed to proactively monitor for corrosion by identifying the key regions of risk for corrosion activity - cathodic protection deficiencies, electrical influences that cause electrolytic corrosion, internal environmental influences and shore power influences.

Be Informed

MarineLinx captures corrosion data and reports it in a simple way, enabling informed decisions to be made. Users benefit from access to previously unavailable information.

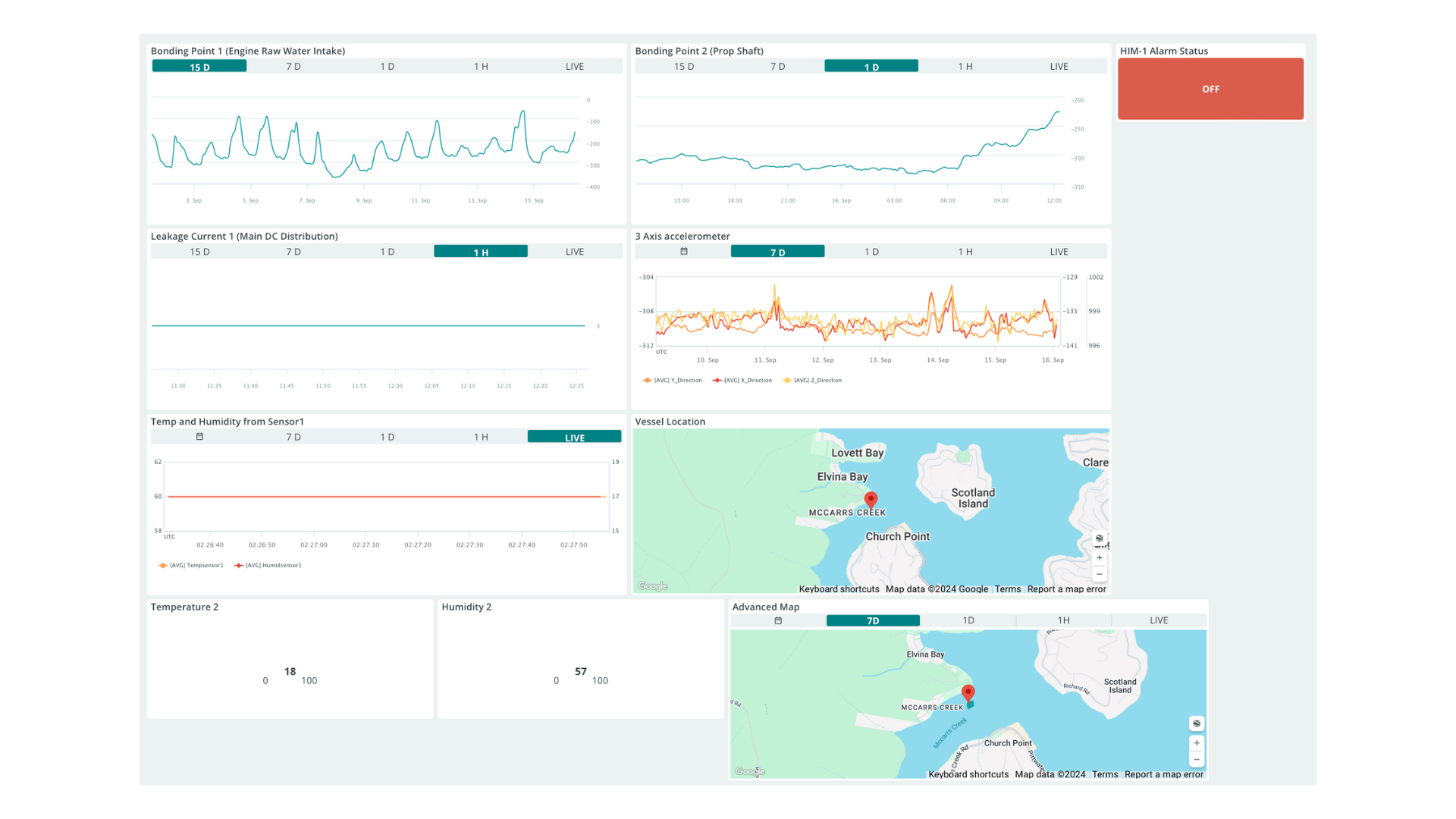

The MarineLinx Dashboard makes reporting easy and simple to understand.

Modular Design

The modular design allows for flexibility in its usage. Vessels can begin with a basic system and gradually incorporate additional features as needed.

Cost Effective Corrosion Control

Leveraging our technology and expertise, MarineLinx simplifies the fault identification process, reducing survey labour costs.

Proactive monitoring reduces maintenance costs and prevents expensive repairs or part replacement due to corrosion damage.

Before: 6 month coating failure

After: 18 month old coating performance

Flexible For Fit

The system is completely flexible for installation making it appropriate for all types of vessels, operational requirements, and sizes. Modules can be stand alone or combined as a complete system.

Take a closer look at the MarineLinx System

MarineLinx Core

Monitors up to 7 reference points for cathodic protection:

Input up to 20 x stray current monitors and shore power monitoring

GPS location input

Input up to 30 x temperature humidity sensors

Input up to 7 x isolation monitors

Connectivity to WiFi for remote monitoring and data logging

Cathodic Protection Sensors

Thru-hull fittings (bronze, aluminium, approved plastic).

Silver-silver chloride reference electrode.

Up to 7 inputs.

Can set high and low tolerances for active monitoring.

DC Isolation Monitor

Standard flush switch fixed panel for active monitoring and alarming of isolation faults on DC systems & AC detection.

Will indicate a positive or negative DV fault with a simple indication for severity from mild to hard ground.

Audible alarm with a mute button.

Can be used stand alone or connected via RJ45 to MarineLinx Core.

Available black or white display.

Current Sensor

Identifies DC stray current.

Constantly tests for unbalanced supply current.

Can be used to monitor AC earthing system for grounding.

Can detect current as low as 1 mA (1/1000th of an amp)

Stand alone or integrated into MarineLinx system.

Optional remote display indicating mA.

Shore Power Monitor

Shore power is commonly blamed for corrosion events on vessels. By actively monitoring all sources of influence from shore power, the user gains accurate information for prevention of shore power related corrosion. Monitors:

DC stray current from shore power

AC stray current from shore power

Imbalanced loads (active - neutral)

Determines a failed earth situation

Temperature & Humidity Sensor

Temperature and humidity are significant influences for rates of internal corrosion to both hull and electrical wiring. Active monitoring will alarm an operator that maintenance is required.

Temperature Measuring Range : -30℃~80℃

Humidity Measuring Range: 0~100%RH

Measuring Precision:

Temperature:±0.5℃ (resolution: 0.1℃)

Humidity:±5%rh (resolution: 0.1 rh)

GPS Montior

GPS Location monitoring and data capture allows MarineLinx to identify if any influences occur at a particular site.

This information can be particularly useful for marinas and vessels that berth at different locations.

Our mission is to change the way owners and operators monitor and manage their cathodic protection.

The purpose of MarineLinx is to improve the ability for the vessel owner / operator to be able to monitor in real time the characteristics that may contribute to the corrosion of their vessel and be warned immediately that a parameter has changed that could be leading to damage of their vessel or running gear.